BASF, BEST, and partners in the automotive industry successfully complete pilot project on chemical recycling

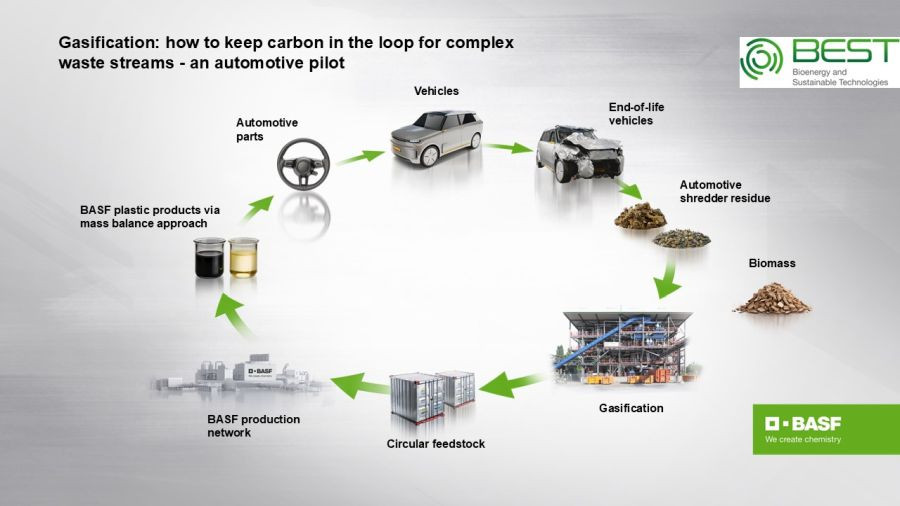

The COMET Competence Center BEST – Bioenergy and Sustainable Technologies GmbH has successfully completed a pilot project for BASF SE on recycling mixed waste from end-of-life vehicles. The pilot project demonstrates the recyclability of high-performance plastics from automotive shredder residues (ASR) together with renewable raw materials. This mixture of plastic, film, paint, and foam residues is so complex that it can currently only be thermally recycled. The pilot project shows that these automotive wastes can be recycled through gasification, a special type of chemical recycling, and returned to automobile production.

This pilot project validates the viability of new sources of plastics and applications for chemical recycling in components. The ultimate goal is to source less primary material in the future and increase the proportion of recycled materials in vehicles. As part of the project, the chemically recycled material was used in the manufacturing process for steering wheels.

(BASF)

The technology enables recycled materials to be used in vehicles and resource cycles to be closed. This means that the use of secondary materials in vehicle manufacturing can be increased. The pilot project will enable the potential of automotive shredder residues as a future source of recyclate and thus as a secondary raw material to be assessed. It is therefore an additional option to mechanical recycling, which often cannot achieve this high level of quality. In addition, in conjunction with the so-called mass balance approach, demand-oriented scaling will be possible in the future.

Defossilization: First fully non-fossil gasification for the production of new plastics

In this project, a combined waste stream consisting purely of automotive waste and biomass was recycled in a gasification process for the first time. The resulting recycled raw material - the so-called synthesis gas and its derivatives - replaced the fossil raw materials in BASF's integrated value chain. Within its production network, BASF then produces the polyurethane formulation needed for the steering wheel using a mass balance approach*.

The recycling innovation uses modern gasification technology from BEST GmbH to convert plastic waste and other residues into synthesis gas at high temperatures.

"In our plant, we have previously converted biomass such as wood or straw into chemical raw materials. In this pilot project together with BASF, we have now used this gasification technology for the first time to convert complex plastic waste streams together with biomass into synthetic crude oil, known as syncrude," explains Matthias Kuba, Area Manager Syngas Platform Technologies at BEST - Bioenergy and Sustainable Technologies GmbH in Vienna. "This form of chemical recycling has great potential for converting complex, mixed waste streams into new, valuable raw materials. It thus represents a sensible alternative to waste incineration.”

(Foto: BEST)

Keep the technology spectrum broad

At BASF, we summarize the three phases of the product life cycle—make, use, recycle—under the heading “Our Plastics Journey.” For the latter, we offer a wide range of recycling solutions, as we are convinced that many methods must complement each other in order to achieve recycling goals. We prioritize mechanical recycling and are continuously improving its efficiency. The type of waste and the degree of sorting determine which technologies are most suitable. We are convinced that complementary technologies such as chemical recycling, which includes pyrolysis, depolymerization, and gasification, are necessary to further promote the circular economy and reduce the plastic waste that still ends up in landfills or is incinerated today," explains Martin Jung, head of BASF's Performance Materials division.

“In order to make optimal use of the various waste recycling options and to further develop all technologies in parallel, an appropriate regulatory framework is essential.”

* Background: Chemical recycling and mass balance

Chemical recycling can process plastic waste that cannot be mechanically recycled for technical, economic, or ecological reasons. Gasification is a variant of chemical recycling that can convert particularly mixed waste streams into valuable new raw materials, for example: plastic production. When fed into large, complex, and continuously operated production plants such as the BASF Verbund, these new circular raw materials are mixed with conventional fossil raw materials and processed into plastic precursors. The new (secondary) raw materials are attributed using the mass balance approach. Products and sites are certified by independent auditors according to internationally recognized systems such as ISCC PLUS or REDcert². Due to the high quality of the new raw materials, the resulting products have the quality of new goods and meet the demanding requirements of high-performance plastics, as they are particularly needed for safety-relevant automotive components.

2025-09-29